David Mueller, President of Insects Limited, Inc. and Fumigation Service & Supply, Inc. is having fun using the bells and the bull from Valenica, Spain to moderate the 11th Fumigants & Pheromones Conference in Krakow, Poland! http://www.FumigationZone.com

Tag Archives: insects

Cleaning is Expensive — Not Cleaning is Even More Expensive

By Curt Lilleodden

So the budget is tight and you need to trim costs. Corners are cut to maximize profits. Which departments are some of the first in line to get the hatchet? Sanitation and Maintenance. Why? Because your Sanitation and Maintenance departments aren’t actually producing your product, and since, theoretically, they are not producing anything, someone up the corporate ladder decides that these departments are areas where money can be saved.

But is this always a wise decision? Ask any sanitation manager and they will emphatically answer “No!” Well, obviously any manager looking at getting their budget sliced is going to be met with resistance. I am here today to help plead their case.

Eliminating positions and hours in your cleaning staff ultimately means reducing the frequency of the cleaning schedule, or at least the depth of the cleaning process. Any area that once was on a weekly cleaning schedule will be reduced to every other week, month, or in some cases, will get eliminated from the schedule altogether. These areas, over time will begin to rear their ugly head, and the results will be pest sources that can sometimes take weeks and months to track down. As the number of reportable customer complaints rises, the plant manager receives a call from corporate headquarters quality department to ask why? In the meantime, products and your company’s good name is at risk.

Consider purchasing a very well maintained used automobile where the oil was changed and chassis lubricated every three thousand miles, tires were rotated every 10,000 and someone was diligent enough to give it a good weekly scrub. You have acquired yourself a “Cream Puff”. You could probably drive this car thousands of miles trouble free, with doing little or no maintenance. But eventually, the engine uses oil, the valves are shot and the transmission starts slipping. The tires wear out early because the front end needs alignment. In fact the whole front end needs to be rebuilt. New spindles and ball joints, new bearings and tie rod ends and to top it all off, rust is starting to show up on the fender tops and rocker panels. And you say to yourself: “What happened? Everything worked so well for so long, and now it is all falling apart at once!” Now, all of the repairs far outweigh the costs of maintaining it in the first place. Get the picture?

The very same thing will happen in your facility if you cut too deep into your sanitation and maintenance budgets. Some areas of the plant can go a long time with “smoldering” pest issues that go undetected. When pest populations in micro environments such as an unused batch bin or product hung up in an idle shipping conveyor reach a saturation point, there can be mass exodus from the source. By the time the source is located, it is too late; the damage has been done. Fertilized females have moved away from the source and have laid eggs in multiple areas of your facility.

Now you have to pay the staff overtime during a holiday shut down to do extensive cleaning. You may have to fog the facility, or possibly fumigate, and pray that you don’t wind up with a product recall. These costs can sometimes far outweigh the costs of regular cleaning and maintenance.

Meet Curt Lilleodden

Curt Lilleodden is the Regional Manager for Fumigation Service & Supply in Iowa, Wisconsin, Nebraska, and Minnesota. Curt and his wife Tammy and four children live in Solon, Iowa. He maintains a fumigation office in Cedar Rapids, IA with three fumigation technicians. Curt comes from Hanska, Minnesota where he grew up on a farm. He graduated from Alexandria Technical College in 1987. Curt spent 19 years in pest control before coming to FSS in 2009. His expertise is in structure fumigations, food safety inspections, commodity fumigations and large food safety pest management programs. Curt enjoys hunting and watching his children’s activities. Curt and Tammy’s daughter Sarah was the first recipient of the FSS Scholarship and she attends the University of Minnesota in Duluth.

Curt stated: ““After spending nearly 20 years in the general pest control industry, I welcomed the opportunity to focus my work on stored product pests. The success of a program to manage stored product pests, probably more than any other group of pests, hinges on the joint effort, cooperation, and communication between the pest control provider and the customer. Building these close relationships with my customers and the results that are realized because of these efforts, has been the most rewarding aspect of my career in pest management.”

C.Lilleodden@FumigationZone.com or 1-319-899-8048

Fumigation Service & Supply, Inc. covers all of the Midwestern United States. We have offices in Indianapolis IN, Bloomington IL, Cedar Rapids IA, Lansing MI, Ft. Wayne IN, Cincinnati OH, and Chicago IL. We feel it is very important to be closer to companies who can benefit from our pest management knowledge and services so when a problem occurs we can be there. If you ever have any questions or concerns regarding insects, rodents or fumigation don’t hesitate to give us a call at 1-800-992-1991 or visit us at http://www.FumigationZone.com.

The 11th International Fumigants & Pheromones Conference will be held June 2-4, 2014 in Krakow, Poland.

The theme of the conference is “Pest Management Around the World.” This educational program includes two days of presentations on current issues in pest management.

Register now at: http://www.insectslimited.com/krakow/

Fumigation Service and Supply Opens New Office in Lansing, MI; Ethan Estabrook is Area Manager

Ethan Estabrook is the Area Manager for the Michigan and Toledo, Ohio territory.

Ethan Estabrook is the Area Manager for the Michigan and Toledo, Ohio territory.

Contact him at E.Estabrook@FumigationZone.com or 517-896-2847 for any fumigation or pest management needs.

See this ad on GRAINNET:

http://www.grainnet.com/articles/fumigation_service_and_supply_opens_new_office_in_lansing__mi__ethan_estabrook_is_area_manager-132555.html

International Association of Operative Millers (IAOM) 117th Annual Conference & Expo

International Association of Operative Millers (IAOM) 117th Annual Conference & Expo – April 29 until May 3

Hundreds of milling professionals from across North America and around the world will convene in Niagara Falls, Ontario, Canada, in 2013 for IAOM’s Annual Conference & Expo. The Conference and Expo will be held at Hilton Fallsview Hotel and Scotiabank Convention Centre, Niagara Falls, Ontario Canada.

FSS will be presenting a booth with many other companies showcasing products, equipment and services designed specifically for the milling industry. Make sure you stop by and see us! FSS will have multiple certified entomologists in attendance at booth 522; we will be more than happy to answer any questions about Grain/Seed/Milling Fumigations and Stored Product Pests. We hope to see you there!

More information – http://www.iaom.info/annualmeeting/

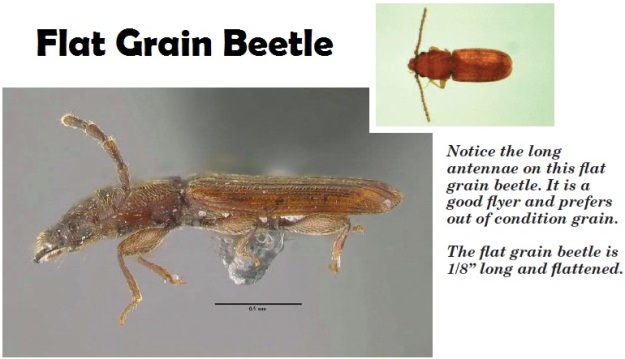

Flat Grain Beetle

A Symptom of a Condition

The flat grain beetle is one of the smallest beetles that attacks stored grain and seed. It can be seen at sunset flying around grain bins. This insect is a secondary feeder that is attracted to moist grain. It is a symptom of a condition, and the condition is out of condition grain. When grain is spilled on gravel it will start to mold when it rains. This moldy condition will attract this tiny brown beetle from great distances away.

Resistance

According to research at Oklahoma State University and Kansas State University, this insect is increasing its level of resistance to phosphine to cause control failure. Considering it lives in near anaerobic conditions, it is a strong survivor of harsh conditions. Resistance testing is important to help the manager dial in the correct dosage rate and fumigant to control flat grain beetles.

Damage

The real damage this stored grain and seed pest causes is its mere presence. The flat grain beetle and other moisture loving insects aggregate in large numbers and can cause the grain to heat up. These hot spots can cause the grain and seed heat damage and a lowering of quality.

Control

If you offer this insect pest what it doesn’t like it will leave or die. Dry sound grain and seed will offer these insects those conditions that it does not prefer and it will leave or die. Fungus feeding insects are symptoms of a condition. Keep it dry.

Food Processing/Distribution

The fumigation needs of the food processing industry have dramatically changed over the past five years. We have helped our food processing customer’s transition with these changes while maintaining and improving product / facility quality. No other industry sector has greater disparity in pest control and fumigation services. Solutions to managing insect issues can be complex. We have the most experience and capabilities to design and implement effective application and pest management strategies. Beyond Fumigation, FSS offers I.P.M. services to the food processing/distribution industry. Our focus on stored product pests from the fumigation perspective gives us the knowledge needed to tackle the toughest rodent and stored product pest issue.

Milling

Our roots as a company are proudly and firmly embedded in the milling industry. The President’s father, Albert Mueller spent 25 years as a miller, eventual head miller and one time president of the Association of Operative Millers. We focus on protecting the quality and integrity of our customer’s flour products. We not only pride ourselves on a high level of quality pest control and fumigation services but lead this industry in successful alternatives to methyl bromide for a sustainable future. Beyond Fumigation, FSS offers I.P.M. services to the milling industry. Our focus on stored product pests from the fumigation perspective gives us the knowledge needed to tackle the toughest stored product pest issue.

View the Grain Fumigation Guide – http://www.fumigationzone.com/docs/GrainGuide.pdf

Check out the FSS family at the 2013 GEAPS Exchange!

GEAPS’ 84th annual technical conference and exposition will bring individuals and companies from around the world to Exchange 2013 at the Kentucky International Convention Center February 23rd to 26th.

GEAPS’ 84th annual technical conference and exposition will bring individuals and companies from around the world to Exchange 2013 at the Kentucky International Convention Center February 23rd to 26th.

FSS is presenting at booth 234 at the Expo Hall along with many other companies showcasing products, equipment and services designed specifically for the grain handling industry.

The Educational Programming Committee has carefully planned another slate of interesting and topical sessions. The Opening Workshop on avoiding catastrophic disasters will kick off the education program Sunday morning. The program will also include the very popular equipment-oriented Expo Pod sessions and the Idea Exchange, which will highlight innovative ideas from industry professionals. Of course, the heart of the program consists of the hour-long educational sessions, and this year’s schedule is packed with useful information which you can take back to your job and implement immediately.

Additional information at: http://www.geaps.com/exchange/index.cfm